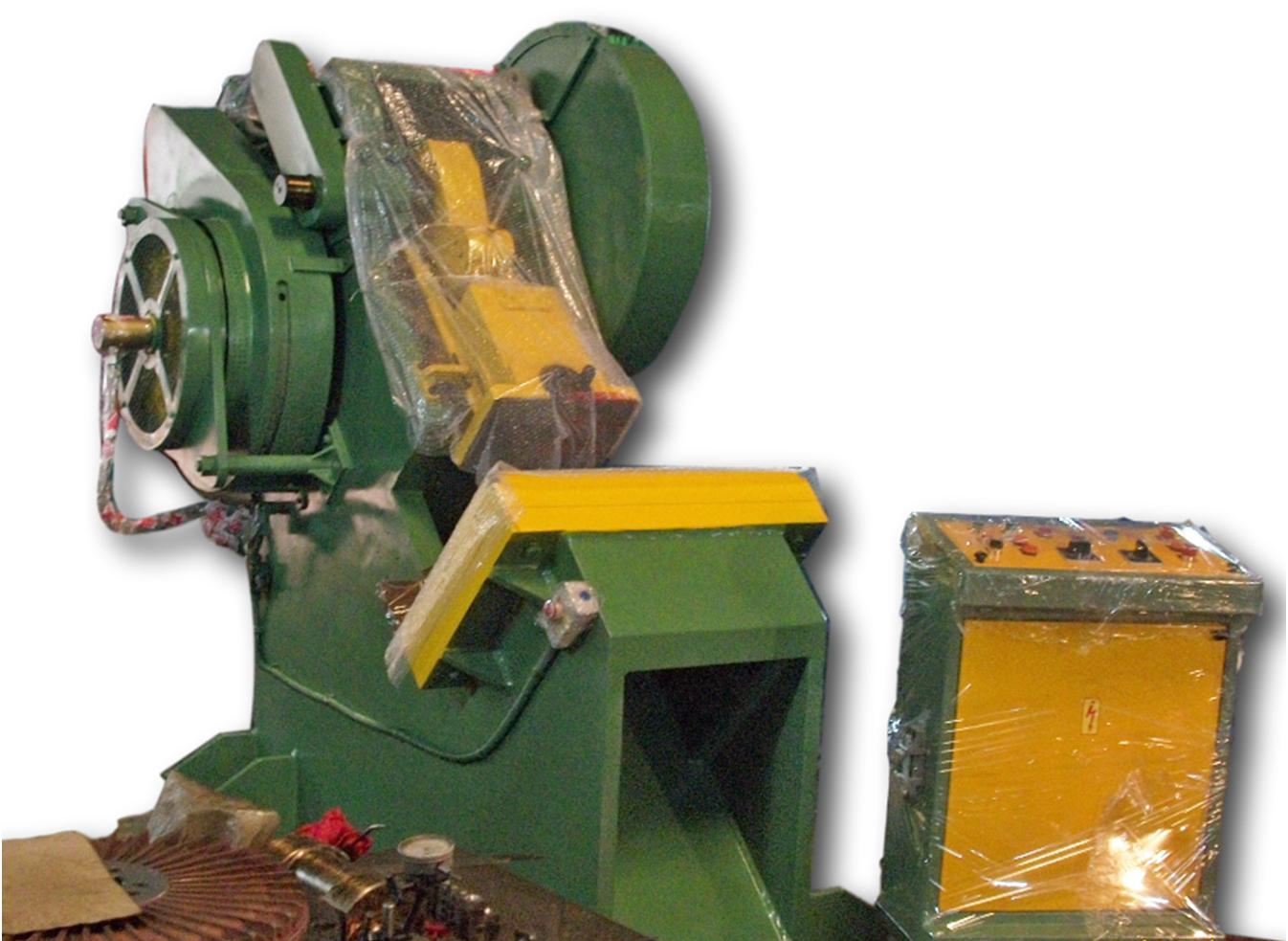

Indo Plus Power Press

Power press is a machine tool that changes the shape of a work piece by the application of pressure.

Left to Right Series:

Range: 10/250 Tonnes in single geared, non-geared, inclinable, non-inclinable or fixed inclined models.

Design features:

- Frame: The frame of the Indo Plus Power Press is rigidly constructed from structural quality steel plates. Frame is designed in such a way that it gives balanced distribution on stresses over the cross section. Welded, one piece construction made from tested fusion welding quality steel and thermally stress relieved before machining ensures minimum deflection and vibrations thus improving die and machine life.

- Main Shaft and Bearings: Normalized medium carbon steel shaft, ground finished on bearing surfaces and heavy walled Nickel Phosphor bearings with hand scaped bores keep bearing pressures low and ensures long working life.

- Slide and guides: Cast Iron slides running in two extra long guides lined with high quality non-metallic liners eliminate slide deflection. Hand scraped bearing surfaces provide smooth movement of slide square to the table resulting in highly accurate press work and extended die life.

- Electrical controls: Easy to see, easy to use main control station with controls for power ON/OFF, START/STOP once ‘inch’ continuous, semi continuous clutch mode selection and clutch on operation with emergency stop simplifies operation greatly. Control supply 230 V, 50Hz.

- Lubrication: Motorized lubricator provides pressurized metered amount of oil to all important points.

- Clutch and Brake: Pneumatically operated clutch-brake combination developed specially for speed operation eliminates overlapping of torque, gives faster action and reduces lining wear to the minimum.

- Other Standard Features: Conveniently located and effortless adjustable slide adjustment mechanism. Stroke adjustment facility in several steps for flexibility in use, standard Bolster, General purpose motor 415V, 3Ø, 50 Hz for presses less than 100T capacity.

- Other Standard Features: Conveniently located and effortless adjustable slide adjustment mechanism. Stroke adjustment facility in several steps for flexibility in use, standard Bolster, General purpose motor 415V, 3Ø, 50 Hz for presses less than 100T capacity.

- Standard equipment with machine: Flywheel and gear guard, bar ejector on slide, air filter, lubricator, regulator, cam limit switch, motorized lubrication system.

- Optional Accessories: Digital Counter, Counter balance, CAM type ejector, air cushion, PLC panel, Variable speed drive, Safety curtain, Anti vibration pads, Hydraulic overload protector.

SPECIFICATION - 10 TO 250 CAPACITIES

(Above 100 tonne capacity, specifications as per customer’s demand.)

| MODEL NO. | UNITS | IEC – 10 | IEC – 16 | IEC – 25 | IEC – 32 | IEC – 40 | IEC – 50 | IEC – 63 | IEC – 100 | |

| CAPACITY AT 20 | ||||||||||

| CRANK ANGLE | TONNE | 10 | 16 | 25 | 32 | 40 | 50 | 63 | 100 | |

| BEFORE BDC AT | ||||||||||

| STANDARD STROKE | ||||||||||

| Stroke Fixed | Standard | mm | 50 | 60 | 80 | 100 | 90 | 90 | 100 | 125 |

| Optional | mm | 20,25,32 | 25,32,40 | 32,40,50, | 32,40,50 | 40,50,63, | 40,50,63 | 50,63,80, | 63,80,100, | |

| 50,63,100 | 63,80,150 | 100110150 | 100110150 | 100125150 | 100125150 | 125160 | 160 | |||

| Stroke | Standard | mm | 8 to 40 | 8 to 50 | 8 to 63 | 8 to 65 | 8 to 80 | 8 to 80 | 8 to 100 | 8 to 125 |

| Adjustable | Optional | mm | 8 to 63 | 8 to 80 | 8 to 100 | 8 to 100 | 8 to 125 | 8 to 125 | 8 to 160 | 8 to 160 |

| Throat | Standard | mm | 170 | 190 | 250 | 250 | 275 | 275 | 300 | 325 |

| Deep | mm | 224 | 280 | 280 | 280 | 315 | 350 | 400 | 450 | |

| Standard | mm | 200 | 224 | 250 | 250 | 280 | 280 | 315 | 355 | |

| Shut Height | Medium | mm | 250 | 280 | 315 | 315 | 355 | 355 | 400 | 450 |

| High | mm | 315 | 355 | 400 | 400 | 450 | 450 | 500 | 560 | |

| Slide Adjustment | mm | 50 | 50 | 50 | 50 | 60 | 60 | 60 | 80 | |

| Slide Face | Standard | mm | 180 x 280 | 200 x 300 | 220 x 320 | 220 x 320 | 250 x 400 | 250 x 400 | 280 x 450 | 315 x 500 |

| FB x LR | Flange | mm | 315 x 400 | 355 x 450 | 400 x 500 | 400 x 500 | 450 x 560 | 450 x 560 | 500 x 630 | 560 x 710 |

| Slide Face Opening | mm | 40 x 60 | 40 x 75 | 50 x 75 | 50 x 75 | 50 x 85 | 50 x 85 | 50 x 85 | 50 x 85 | |

| Dia x Depth | ||||||||||

| Clear Distance | mm | 250 | 280 | 315 | 315 | 355 | 355 | 400 | 450 | |

| Between Upright | ||||||||||

| Height of table | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 900 | |

| Surface from Floor | ||||||||||

| Size Of Table | Standard | mm | 350 x 500 | 355 x 560 | 400 x 630 | 460 x 630 | 500 x 710 | 520 x 710 | 550 x 800 | 600 x 900 |

| FB x LR | Deep | mm | 400 x 500 | 450 x 560 | 500 x 630 | 500 x 630 | 560 x 710 | 560 x 800 | 630 x 800 | 710 x 900 |

| mm | 400 x 630 | 450 x 710 | 500 x 800 | 500 x 800 | 560 x 900 | 600 x 800 | 630 x 1000 | 710 x 1120 | ||

| Opening in the Table | mm | 160 x 200 | 180 x 224 | 200 x 250 | 200 x 250 | 225 x 280 | 225 x 280 | 250 x 315 | 280 x 335 | |

| x 200 | x 224 | x 250 | x 250 | x 280 | x 280 | x 315 | x 335 | |||

| Bolster Thickness | mm | 65 | 70 | 75 | 75 | 80 | 80 | 85 | 100 | |

| Stroke per | Geared | SPM | 70 | 63 | 50 | 50 | 50 | 50 | 45 | 40 |

| Minute | ||||||||||

| Motor | Geared | kW/rpm | 0.75/1500 | 1.5/1500 | 2.2/1500 | 2.2/1500 | 3.7/1500 | 5.5/1500 | 5.5/1500 | 7.5/1500 |

| Approximate | Geared | cm | 111x74x225 | 124x95x250 | 132x110x263 | 132x110x263 | 184x134x313 | 195x142x337 | 205x150x360 | 240x180x380 |

| Overall Size | ||||||||||

| FB x LR x Ht. | ||||||||||

| Approximate | Geared | Kg | 750 | 1650 | 2500 | 3000 | 4500 | 5000 | 6000 | 8200 |

1. Shunt height at standard maximum stroke is the distance between table surface and slide face with slide at bottom of stroke adjustment .

2. For strokes less than standard maximum, the shut height will be increased by half the difference, for strokes more than standard maximum,

the shut height will be redused by half the difference in stroke.